Freeform Injection Molding has Scaled-Up

Print. Inject. Dissolve.

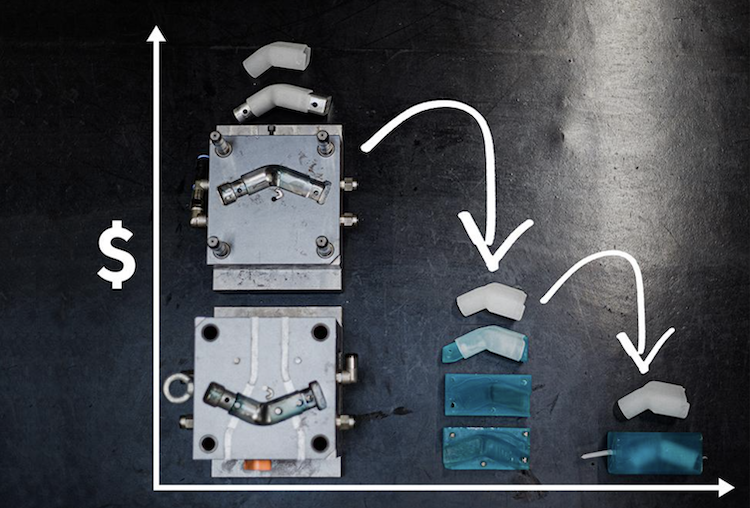

3D-printed injection mold tooling is transforming product development, and Addifab is transforming 3D-printed tooling with soluble molds.

Freeform Injection Molding starts with the 3D-printing of injection mold tooling inserts. These inserts serve the same function as the cores and cavities in conventional metal molds, only more sustainably. And you can fill them with your regular feedstocks using your standard injection molding machines; from the softest rubbers to the hardest metals, for unseen flexibility.

The Freeform Injection Molding Scale-Up Platform

The Scale-Up Platform is Freeform Injection Molding for industrial manufacturers. A high- powered tool chain that brings the entire range of injection moldable materials into the additive manufacturing domain. Are you looking for cheaper, faster, and more sustainable tooling? Are you required to use a specific set of materials? Are you ambitious about bringing new value to your customers? Then the Scale-Up Freeform Injection Molding platform is the choice for you!

You get unseen design freedom with unseen material selection – all on the same platform. You get the NXE 400 3D Printer and accessories from renowned supplier Nexa3D. You get your mold design software, tooling resins and demolding station from Addifab. And you get to drive down your costs on low-volume injection molding.

With the Scale-Up Platform you enable product development of 3D printed injection mold tooling at 15% of the cost, 12% of the time, and with 75% CO2 emissions reductions, compared to a regular steel tool.

Stop prototyping, start producing – with the Scale-Up Platform from Addifab & Nexa3D.

Ready to learn more about Freeform Injection Molding?

Fill out the form below and one of our Additive Manufacturing Specialists will reach out within 1 business day.